2006-2008

Archaeological Investigations in Khao Sai On archaeological district (Lopburi Province)

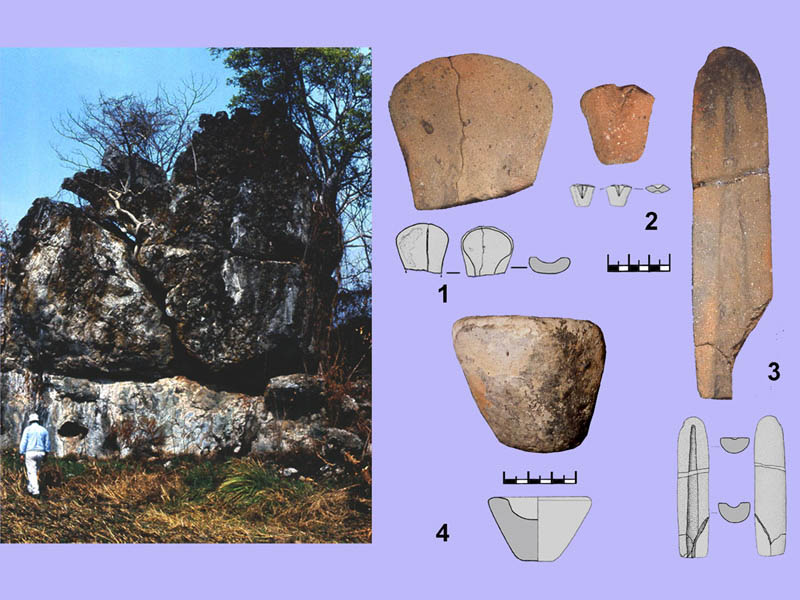

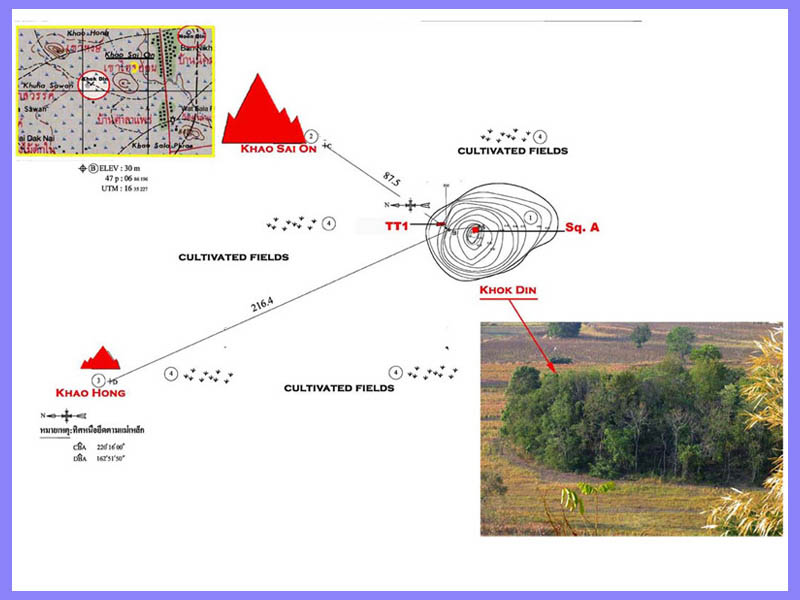

In 1989 Mauro Cremaschi, carrying out the geomorphological survey of the Lopburi Plain comprised between the Khok Samrong district and Lopburi city, called our attention on the Khao Sai On dioritic inselberg (74 m asl; 14°47’9.70”N, 100°43’51.97”E), at ca. 10 km east from the Lopburi city centre. In this area we also noticed a small mound of waste consisting of fragmented cupriferous rocks, slag and potshards of technical and domestic ceramics (Locus 1, later called Khok Din), a tiny inselberg nearby, where we found few terracotta casting moulds and crushed copper ores (Locus 2), and a large rocky formation of diorite with copper mineralizations (Locus 3) pierced by several rounded and deep shafts, probable evidence of an ancient mining site (Fig.s 1-2).

In 2006 we surveyed again the KSO hill looking for mining shafts. At the hill top dense shrubs and acacia scrub only allowed us to observe some vertical cuts of the dioritic rock with quartz veins associated to copper mineralizations. On the east side of the hill a large depression, with randomly scattered heaps of parent rock, also hints at an open pit mine (Fig.s 3-4).

Our observations on the distribution of minerary/smelting sites around the KSO inselberg were refined and enlarged in 2009 by a systematic, intensive and controlled survey conducted by Thomas Oliver Pryce and his team.

Overall, data collected in the KSO area in 1989-90 indicated a close correlation with what the “Thailand Archaeometallurgy Project” (TAP) was uncovering in the large prehistoric copper mining and smelting sites in the Khao Wong Phrachan Valley, few kilometres north of KSO. The hypothesis of an emergence of bronze metallurgy as a regional phenomenon in the Lopburi river valley, starting from the end of the second millennium BC, deserved to be tested in the KSO area.

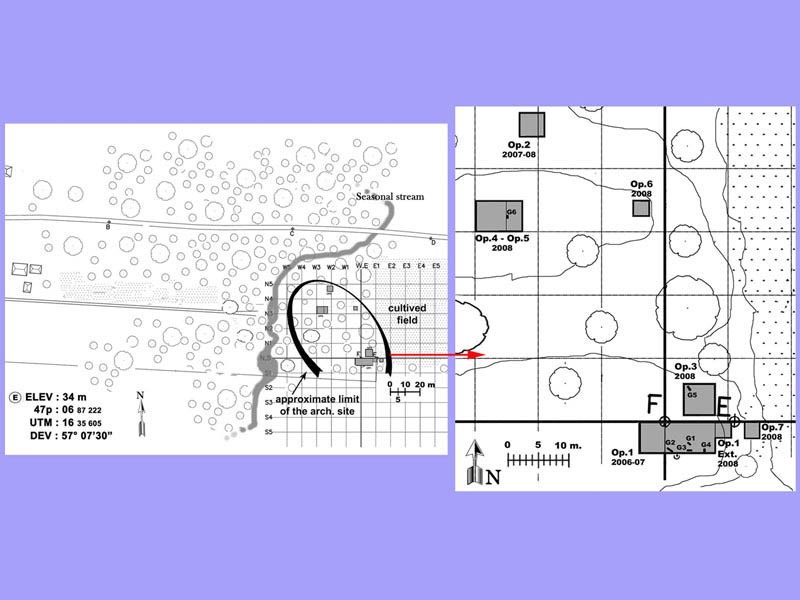

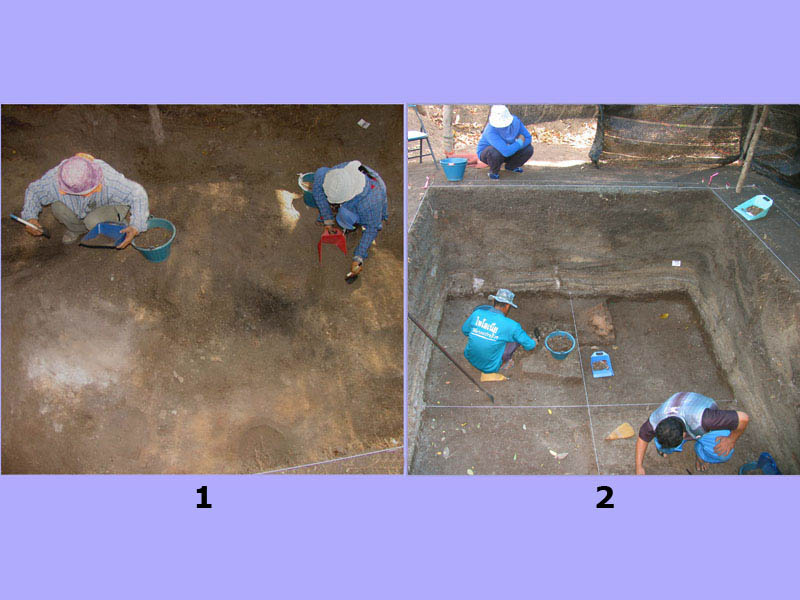

Therefore, LoRAP began stratigraphic investigations in two sites in the KSO area: in 2006 we opened two test trenches, which were followed by larger excavations in 2007 and 2008.

The first site (former Locus 1), locally called Khok Din (ca. 0.22 ha;) about 90 m south of KSO, is a low mound covered by wild vegetation. The small mound, unsuitable for agriculture, is made up of metallurgical residues: grit from treatment of the parent rocks mixed to crushed copper slag, bivalve terracotta casting moulds, and shards of technical and domestic ceramics. Such an assemblage was indeed alike the evidence the TAP had excavated in the industrial and residential site at Nil Kham Haeng in the Khao Wong Phrachan valley (Fig.s 5-6).

The second site, located between a large cultivated field and a patch of residual tropical forest crossed by a seasonal stream, showed no surface archaeological evidence, nor did it have a name. The villagers have reported to us random findings of “ancient things”, including “metal”, potshards and skeletal remains: enough to suspect the presence of an ancient cemetery in the area which we (optimistically) decided to call Noen Din (Soft soil).

KSO-Noen Din

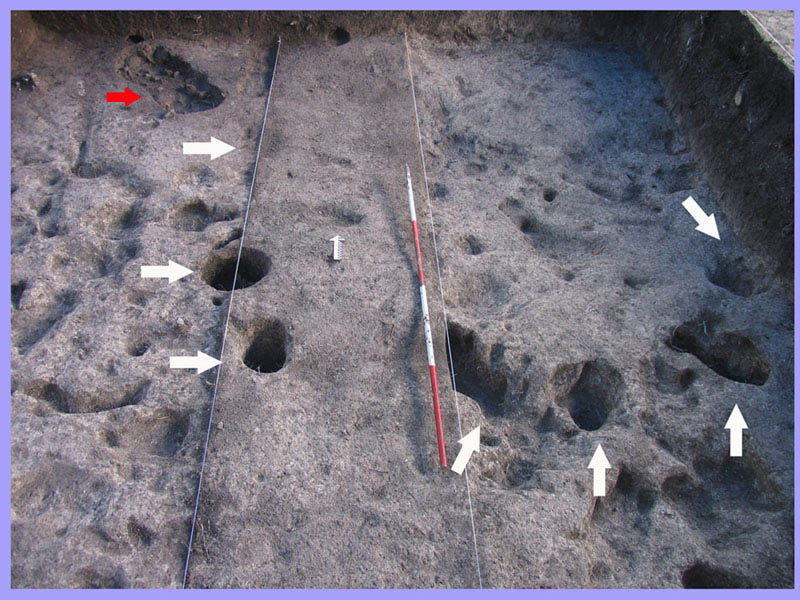

At Noen Din (ca. 1.5 km NE of KSO; 14°47’16,66” N, 100°44’23.67 E) over an area of 156,25 m2 we discovered a single archaeological layer of residential dumps, scattered graves and metallurgical waste resulting from the treatment of copper ores (Fig. 7).

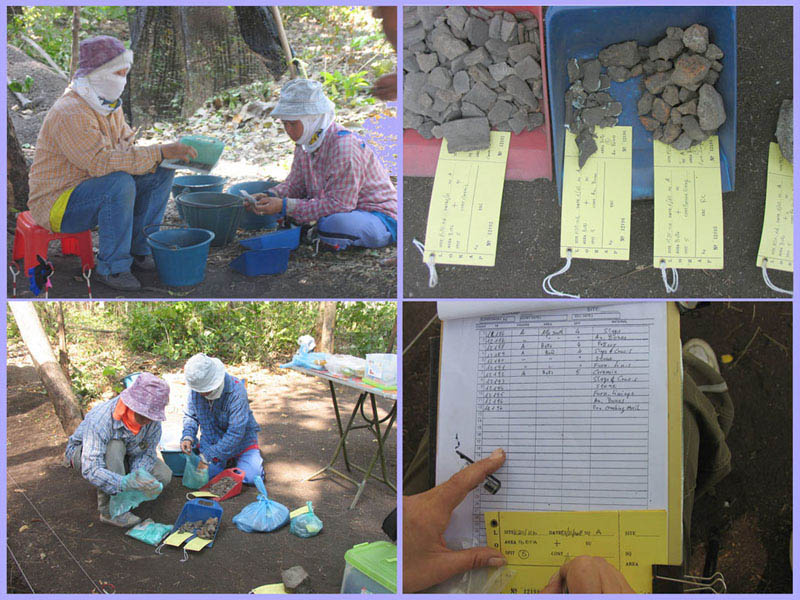

The dumps contained fragments of earthenwares (domestic pots, crucibles, ‘perforated chimneys’, bivalve moulds) and animal bones in a silt-clay matrix mixed with fragments of slag and host rocks (Fig. 8).

Clusters of post holes were sometimes associated with pit burials of children, while several adult burials have been found in the southern area of the site. In total three adult and three child burials were excavated (G1-6). Unfortunately, most of the cemetery must have been in the southernmost part of the site, on a land where we were not allowed to dig. The elderly owner of that lot (who was always flanked by a couple of unfriendly-looking Rottweilers) feared that the spirits of the dead, disturbed by our excavations, might retaliate against her (Fig.s 9-10).

Worth mentioning is burial G.6 that contained the remains of an infant provided with a necklace of 18 carnelian beads and an anklet of shell beads, three ceramic vessels and nine halves of casting moulds. The vases had undergone repairs before being placed in the grave, while the moulds, being unmatched, could not be used in pairs. Although these were waste items, it is clear the exceptional nature of the burial rite set up for this infant. The moulds are in fact usually found in special adult graves, of the type called “founders’ burials”. Therefore the burial furniture of G.6 was not intended as a reflection of what the dead, being a child, exercised in life, but as a wish for an afterlife where the deceased would perhaps have probably followed an activity linked to a family tradition (Fig. 11).

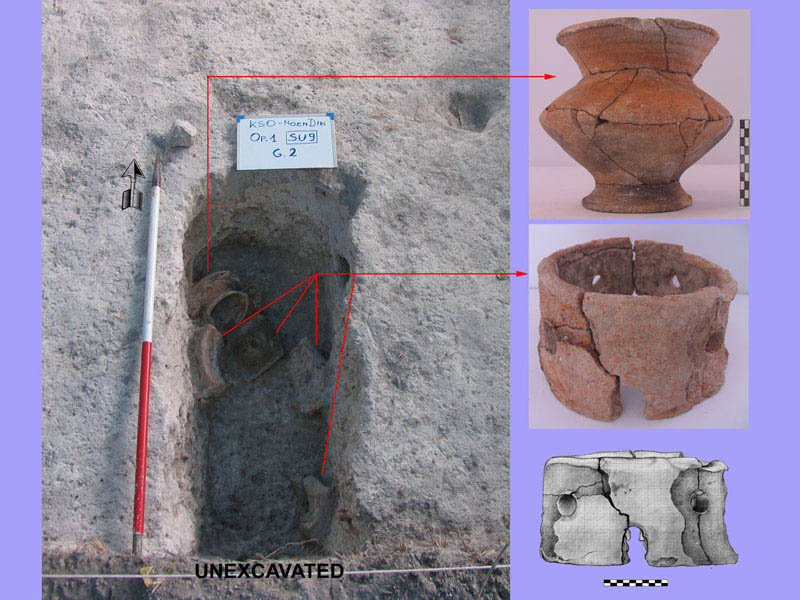

A true “founder’s burial” was indeed that of the adult (G.2) accompanied by a ceramic pot, two cornelian beads, one glass bead, and by a terracotta “perforated chimney” disassembled in five pieces distributed inside the pit (Fig. 12). These “perforated chimneys”, we assume to be part of a copper smelting installation, represent an original technological innovation, not documented in other metallurgical contexts outside the Lopburi region, introduced in the copper-reduction process by local founders during the mid-to-late Iron Age (Fig.s 13-14).

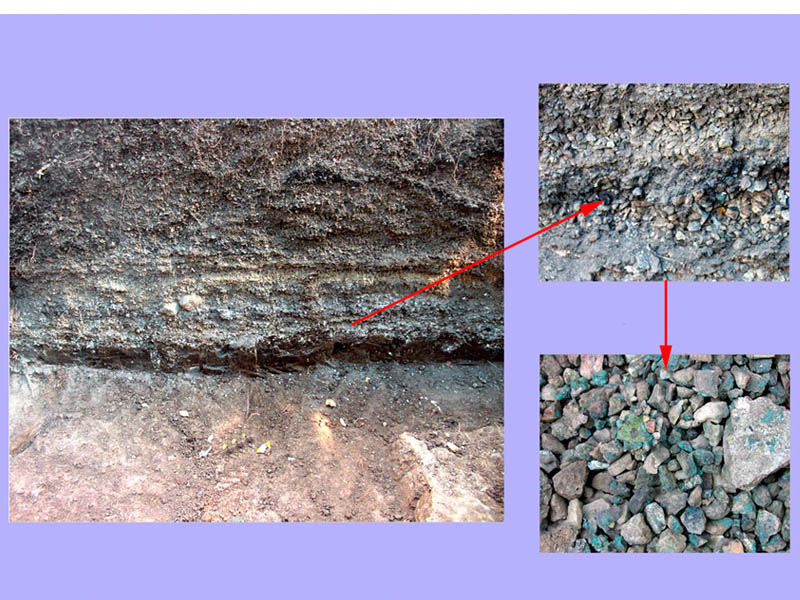

KSO-Khok Din

This low mound of metallurgical wastes (14°47’04.07” N, 100°43’47.78” E) (ca. 2 m thick) consists of a sequence of “activity floors” for the beneficiation and the reduction of copper ores, alternating to thick lenses of host rock grit mixed with fragments of slag of millimetre size, fragmented hammer and anvil stones, terracotta crucibles and furnace chimneys, and shards of domestic ceramic [Fig.s 1, 5-6]. Two completely decayed clay structures, bordered by clusters of tiny charcoals and large ash stains, in the basal layer might be related to smelting installations (Fig.s 15-16). This deposit, in accordance with the domestic and technical ceramics types, was formed between the very late 1st millennium BCE and the first half of the following one.

Both sites provide excellent examples of the intensive exploitation of local copper ores, triggered by the ongoing growth of social complexity in the Lopburi Plain since, at least, 500 BCE. Various technological innovations, including iron tools and weapons, more effective agricultural techniques, and inter-regional exchanges accelerated the formation of local elites, whose demand for bronze goods triggered a real ‘copper rush’, likely run by small groups of “peasant-founders”. Indeed, while copper-base artefacts (mainly small axe-adzes) found at ‘Bronze age’ sites (ca. 1100-500 BCE) in the region are exceptionally few, by the end of the ‘Bronze age’ and more so in the ‘Iron age’, bronze ornaments and tools number in the hundreds (Fig.s 17-18).

Fig. 18 – 2008. The LoRAP team with Pisit Charoenwongsa (center), a pioneer of Thai prehistoric archeology, and former Director of the SPAFA-SEAMEO.